The research titled “Design and Development of the Rainer Conveyor Module Based on Omron CJ2M CPU-31 PLC and Omron NB7W Human Machine Interface (HMI)” has been successfully completed by a research team consisting of Muhammad Rakha Firdaus, Imroatul Hudati, Hidayat Nur Isnianto, and Sihno Priyatno. This study focuses on the design and development of an automated conveyor system using the Omron CJ2M CPU-31 Programmable Logic Controller (PLC), widely known for its reliability in controlling various industrial processes. In addition, the study incorporates the Omron NB7W Human Machine Interface (HMI) technology as an interactive visual interface, allowing users to monitor and control the entire process more easily and in real-time. The main objective of the research is to enhance the efficiency and effectiveness of industrial system control, particularly in the manufacturing sector, with the hope that the results can be implemented to optimize production processes, reduce human error risks, and provide a more modern and reliable technological solution.

In the field of industrial automation, understanding the ongoing processes requires a device capable of depicting the entire industrial flow in a simple, easy-to-understand system that is user-friendly for operators. Currently, many devices have been developed to support learning and the implementation of industrial automation processes. However, many of these devices still have some weaknesses. Some of the shortcomings include poor integration between different systems, limited component variety, which reduces flexibility in simulating more complex industrial processes, and the lack of Human Machine Interface (HMI) technology that could enhance user experience in monitoring and controlling systems.

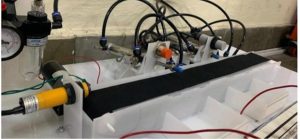

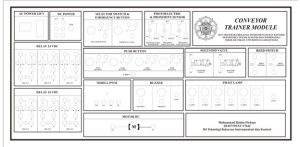

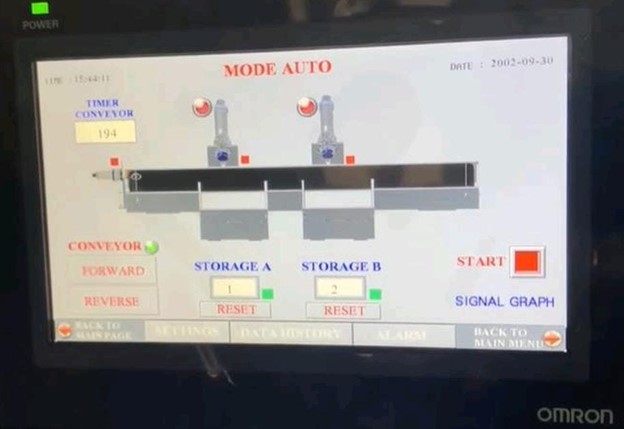

To address these issues, this research designed a Conveyor Trainer Module fully integrated with PLC and HMI. This device is specifically designed to combine the PLC input/output (I/O) components with pneumatic systems and conveyor systems, enabling the simulation of sorting machines commonly used in the industry. The sorting machine is designed to separate objects based on material type, such as distinguishing between metal and non-metal objects. The device includes not only mechanical components like conveyors and pneumatics but also integrates HMI software, providing visual control and monitoring.

The development process of this device involved a series of functional tests on each component, both individually and systematically, as well as comprehensive testing of the entire system. These tests were conducted to ensure that all components function properly and can work seamlessly together in one integrated system. The results from the tests show that the Conveyor Trainer Module successfully integrates the PLC, PLC I/O components, pneumatic systems, and conveyor system into one functional and efficient system. The system is capable of effectively simulating a sorting machine, especially in the automatic separation of metal and non-metal objects.

Additionally, the Human Machine Interface (HMI) developed in this study proved capable of real-time monitoring and control of the entire process within the system. Users can easily understand and operate the system through the intuitive HMI, thereby speeding up the learning and implementation of industrial automation technology. This demonstrates that the designed device is not only successful in technical aspects but also in providing ease of use for operators or end-users, making it more effective in supporting industrial process training and simulation activities.

This research contributes to several points in the Sustainable Development Goals (SDGs), particularly:

- SDG 9 – Industry, Innovation, and Infrastructure: The research aims to develop automation technology in the industrial sector, such as conveyors and sorting machines, which can enhance production efficiency. The use of PLC and HMI enables the integration of modern, innovative technology, supporting smarter and more sustainable industrial infrastructure.

- SDG 4 – Quality Education: The development of the Conveyor Trainer Module supports interactive and comprehensive learning in industrial automation technology. This aligns with the goal of providing quality education and access to learning tools relevant to the workforce and technological advancements.

- SDG 12 – Responsible Consumption and Production: By automatically separating metal and non-metal objects, the system supports more efficient and environmentally friendly manufacturing processes, potentially reducing waste and promoting more responsible production practices.

This research demonstrates how technology can be leveraged to advance innovation in industry and education, while also supporting sustainable production practices.